Introduction

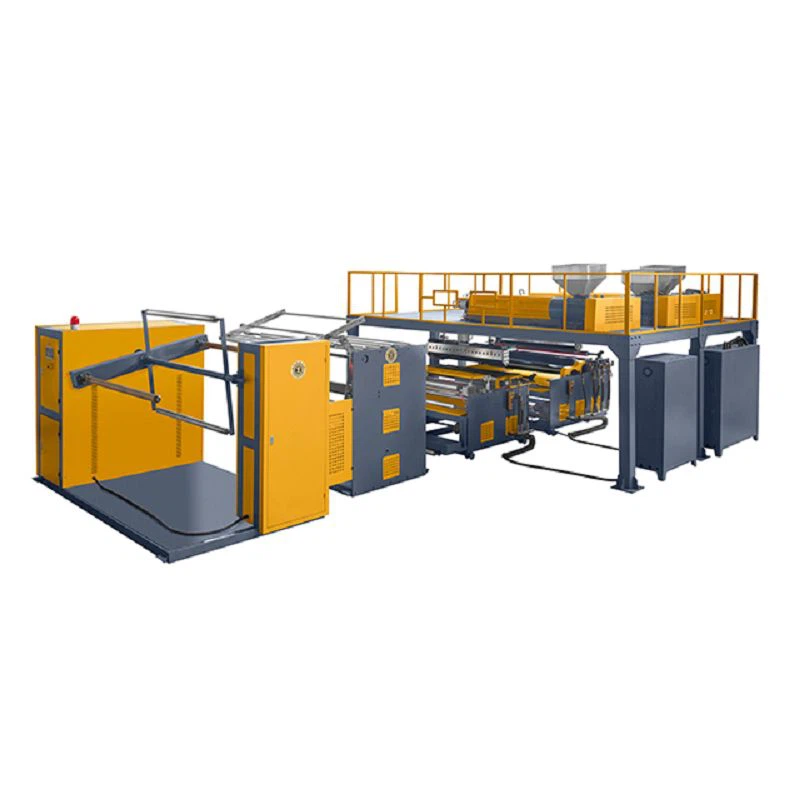

The Air Bubble Wrap Making Machine is commonly used in various industries for packaging and protecting different items. Its application is widespread, ranging from electronics and instruments to ceramics, glass, cosmetics, food, textiles, furniture, and more. This versatile machine consists of several essential components, including a feeding part, heating part, stretching part, bubble-making part, cutting part, and other necessary parts. It is compatible with various materials such as HPDE, LLDPE, pearl film, aluminized film, allowing the production of bubble films in different sizes and shapes.

Features

The Air Bubble Wrap Making Machine is highly efficient due to its automated control system. Unlike traditional manual equipment, it can extrude up to 300 kg of materials per hour and its mechanical speed can reach 40m/min. The machine is equipped with a double-layer knurled wheel that provides strong clamping force and guarantees stable transportation of materials. The heating system is controlled by stepless frequency conversion technology, ensuring that the heating is uniform, energy-saving, and efficient. Users can easily adjust the temperature and speed settings using the control panel. Precise stretching is achieved through the pneumatic system control, ensuring that the film is flawless and the product quality is improved. Overall, the Air Bubble Wrap Making Machine is a valuable addition to any manufacturing process.

Working principles

The resin materials of various types are thoroughly mixed in specific proportions before being introduced into the extrusion molding machine. Under high temperatures, the mixture is melted and then passed on to the film-blowing machine. Through the injection of air, it is transformed into a cylindrical film, which is later divided into two pieces. By utilizing a pressure roller, the two-layer film is molded into a thin double-layer shape. This shape is softened by heating and carefully wound around a vacuum-forming roller with circular perforations. As a result, a vacuum bubble is created by drawing in a thin layer of material through the round holes. These bubbles offer multiple benefits such as cushioning the impact of collisions on objects, shielding against external influences, and ensuring the safety and protection of the items.

With over 10 years of experience, Zhetuo Machinery Co., Ltd. is a privately owned company with an impressive yearly production value exceeding 90 million.

Our company is dedicated to keeping up with the constantly evolving global packaging machinery industry. We strive to provide our customers with the highest quality machinery products at prices that are competitive and accessible to all. With a team of skilled and knowledgeable technical staff, we are able to provide our customers with outstanding after-sales service that is both timely and comprehensive. Our commitment to excellence is evident in everything we do, and we look forward to continuing to serve both new and loyal customers far into the future.

Mechanical performance parameters

| Product Name: | Air Bubble Wrap Making Machine |

| Scope of application: | Some of the types of films available in the market today include HPDE and LLDPE resin films, pearl films, co-extrusion films, and aluminized films. These films are widely used in various industries such as packaging, construction, and agriculture. HPDE and LLDPE resin films are commonly used for their excellent impact resistance, flexibility, and chemical resistance. They are widely used in the packaging industry to manufacture bags, pouches, and wraps. Pearl films, on the other hand, offer a unique, pearl-like appearance that adds an attractive element to packaging design. They are commonly used in the cosmetics and food industries. Co-extrusion films are made by combining two or more types of plastics to create a combination of properties that cannot be achieved with a single plastic. These films are commonly used in the packaging industry to manufacture bags, pouches, and wraps. Aluminized films are coated with a thin layer of aluminum to provide insulation and moisture barrier properties. They are commonly used in the construction industry to manufacture insulation sheets and roofing materials. In conclusion, the availability of a wide range of films in the market today has made it possible for industries to choose films that best meet their needs in terms of strength, durability, appearance, and other properties. |

| The maximum width of raw material unwinding: | 1200mm |

| Maximum diameter of raw material unwinding: | 800mm |

| Maximum width of product winding: | 1200mm (standard width 10mm-1200mm adjustable) |

| Maximum diameter of product winding: | 1500mm |

| Maximum mechanical speed: | 40m/min (the actual production speed is determined by the materials used and production process requirements and other conditions) |

| Maximum extrusion volume: | 300KG/h |

| Maximum extrusion thickness: | 180gsm |

| Minimum extrusion thickness: | 50gsm |

| Extrusion thickness uniformity: | 3% |

| Mechanical voltage: | 3-phase 4-wire, 380V, 50HZ |

| Power supply: | 110KW |

| Mechanical size: | 11mX5.5mX3.5m (LXWXH) |

| Mechanical weight: | 7000KG |

The main configuration data of the machine

| Effective width of die head: | 1800mm |

| Extrusion screw diameter: | 75mm, 70mm, 70mm |

| Reducer model: | 173,173,173 |

| Main motor power: | 22KW, 22KW, 22KW |

| Inverter power: | 22KW, 22KW, 22KW |

| Bubble Roller Diameter: | 270 |

Our mode of transportation

Hot Tags: air bubble wrap making machine, China air bubble wrap making machine manufacturers, suppliers